Controlled Environment

Stable, climate-controlled spinning conditions for reproducible results

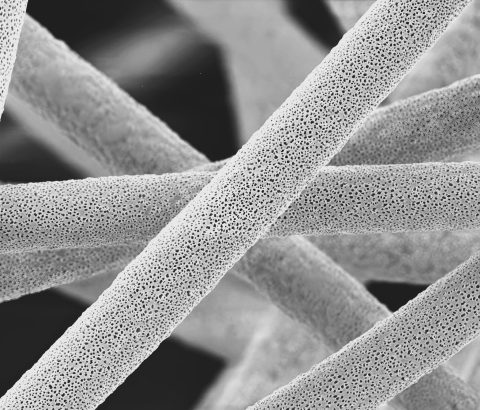

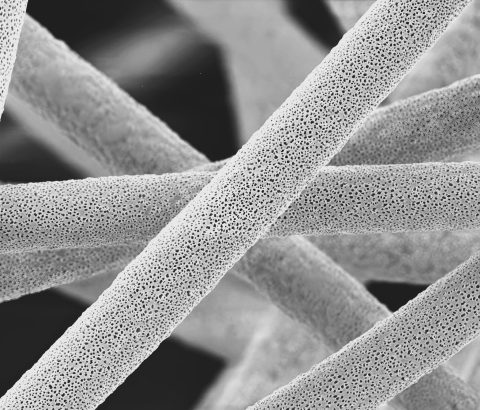

VIVOLTA’s EC-CLI R&D electrospinning system is our premier electrospinning machine for precise, climate-controlled nanofiber production. It is the same platform we rely on in our own medical electrospinning development and manufacturing, helping partners bring next-generation electrospun medical devices and materials to life.

With built-in climate control, modular hardware and advanced automation, EC-CLI is designed to make electrospinning more consistent, reproducible and scalable for demanding research teams.

Since 2008, our team has supplied high-quality electrospinning machines to leading universities, research institutes and medical device developers worldwide – first as IME, and now as VIVOLTA.

Stable, climate-controlled spinning conditions for reproducible results

Consistent fiber morphology and scaffold thickness

Faster process development with less trial-and-error

Easier transfer of parameters into larger-scale systems

Flexible, modular design for customizable processes and versatile applications

Best-in-class professional-grade R&D system for the most challenging R&D projects

High-quality electrospinning starts with a stable environment. EC-CLI’s fully integrated climate control comes standard on every system – there is no need for a separate climate chamber.

Independent sensors inside the spinning chamber continuously compare actual values to setpoints, keeping your process stable even during long experiments.

The EC-CLI electrospinning machine is built on a modular design, so you can configure it around your research instead of adapting your experiments to the hardware.

You can configure, for example:

Many of these modules are part of our dedicated Electrospinning Equipment range and can be added over time as your program grows.

High-voltage configurations (standard positive nozzle / negative collector)

Multiple translating nozzle stages and multi-nozzle options

Flat, rotating and custom collectors – including low-temperature and spoke collectors

Optional HEPA filtration, gas shielding, real-time thickness measurement and anti-statics

With EC-CLI, you can create a wide range of electrospun structures:

Independent control of nozzle and collector stages, plus co- and coaxial spinning options, make it possible to engineer complex fiber architectures tailored to your application.

EC-CLI uses a standard positive nozzle / negative collector configuration, with:

Built-in voltage ramp functionality improves process stability when producing thicker scaffolds or running long experiments, helping you maintain reproducible results from run to run.

The EC-CLI system is designed to fit smoothly into busy labs:

To reduce manual variability and support robust documentation, the EC-CLI electrospinning machine includes:

This helps your team document conditions precisely and speeds up process optimization.

Safety and environmental control are built into the machine architecture:

These features help maintain a clean, safe working environment that meets institutional requirements for solvent handling and particle control.

EC-CLI electrospinning machines are used across a wide range of application areas, including:

Because the same platform is used inside VIVOLTA’s own CDMO operations, the EC-CLI is well aligned with requirements for regulated medical device development and manufacturing.

The EC-CLI machine’s fully-integrated climate control technology sets it apart, giving you ultimate control of your research. While other systems rely on additional modules, VIVOLTA’s climate control unit comes standard on all EC-CLI systems, because high-quality, reproducible electrospinning requires it.

The EC-CLI electrospinning machine and add-on equipment offers advanced functionality to meet the most demanding research needs. A wide range of plug-&-play modules seamlessly integrate with the core system taking your research to the next level.

Enhance efficiency and reduce human error with the EC-CLI system’s advanced process automation features. Real-time monitoring and comprehensive data logging capabilities enable precise tracking and analysis of your experiments. Programmable “teach in” functions allow you to automate processes, ensuring consistent and reliable results with minimal manual intervention.

Experience intuitive operation with the EC-CLI system’s full-color touch panel and user-friendly interface. Designed for ease of use, the EC-CLI system requires minimal setup time, allowing researchers to start their experiments quickly and efficiently. Whether you are new to electrospinning technology or an experienced user, the EC-CLI system’s interface simplifies the process, making it accessible to all.

Ensuring the safety of researchers and maintaining a clean working environment are paramount with the VIVOLTA EC-CLI electrospinning machine and add-on equipment. The CLI’s safety and environmental control features ensure that your research is conducted in a safe and clean setting.

Constructed with high-quality materials and durable components, the EC-CLI electrospinning machine and add-on equipment ensures long-term reliability and performance.

20–45 °C, 10–80% RH with tight tolerances.

Integrated fume hood and safety interlocks.

Configurable voltage and multi-nozzle options.

Flat and rotating collectors, with custom geometries possible.

Optional real-time thickness measurement module.

Data logging and process automation features.

Compact laboratory footprint with large working volume

Investing in an electrospinning machine is only the first step – how you use it matters just as much.

On-site or remote training for new and experienced users

Application consulting to help design and optimise experiments

Global service and maintenance support including the US, Canada, Europe, Australia, Japan, China, and Korea

Ongoing access to our electrospinning specialists for technical questions and process guidance

"*" indicates required fields